Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Brand: VESTA

Packaging: Wooden Crate

Supply Ability: 100%

Why need SMED Quick Die-Change System:

With the increasing competition in the market, plastic products faster replacement, the coexistence of more and more varieties, many varieties, small batch production, Francis production will become the mainstream, especially for the automotive industry supporting enterprises, whether it is or will be interior trim, parallel, for different models of complete. Provide qualified products. Therefore, the time interval of the mould replacement will become increasingly short, that is to say the mould replacement frequency will be higher and higher, the corresponding injection molding machine downtime will greatly increase, seriously affect the production efficiency and machine utilization rate, the delivery period is prolonged, large investment can not be effectively return. This situation has caused the domestic production and use of injection molding machine manufacturers attention, in the injection molding processing automation if not effectively solve the problem of quick die change, other production automation degree high is difficult to fully To improve the utilization rate of equipment, improve production efficiency, the whole set of equipment can only be regarded as strong, flexible response to "lame". And this problem in Western industrialized countries has been basically solved, namely: the quick die change system.

Developping stage:

(1)Pull type rotary machinery

This is a quick die change system early, typical products from the Swiss company "Staubli". The characteristics of the system are: die clamping back center, suitable for small and medium-sized injection molding machine. The mechanical structure is more complex, in the rear part of the mould clamping force back center. The advantages of this system are: die around completely open, no any clamping element for external pipe plug. The system's weakness is: die back shall be installed with uniform clamping mechanism. The clamping force and no back around, wear large mold deformation work, clamping parts of the component wear serious, no clamping element state feedback signal supply system installation, host. Maintenance is difficult, not suitable for retrofitting existing equipment.

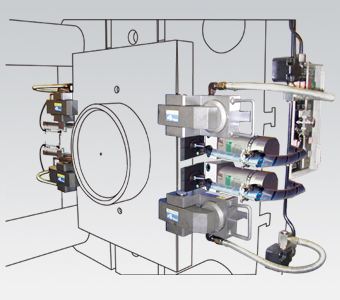

(2) Hydraulic press plate

This is the most widely used rapid die change system, typically from Enerpac, US Aerostar, Pascal from Japan.

Now in Ningbo China,we R&D ourselves,and develop our own hydraulic press plate,widely applied in injection and stamping/punching/die casting facilities during the process of die change/mold change.

(3) Magnetic chuck type

This is the rapid development in recent years, American industrial developed countries is widely accepted and adopted the quick die change system, typical products from Italy TECNOMAGNETE (tecnomagnet) company, has more than 10 years of development of this product, production and application experience of nearly 10000 system is applied to all over the world, especially for the automotive industry supporting manufacturers. In recent years, the Swiss Staubli company and Pascal company of Japan also started from the traditional hydraulic steering system for mold development and sales force system. The system is characterized by structure and control is very simple, without any mechanical clamping elements and movement in the mold plate and the suction pole on the contact surface, no matter is the heart or peripheral, all permanent magnetic clamping, injection molding machine is suitable for various types and specifications. The advantages of this system are: convenient installation, hydraulic and fully electric injection molding machine is suitable for various specifications, clamp Force from the permanent magnetic materials, without electrical work, a clamping state real-time signal feedback to the host, to ensure absolute safety clamping; full contact surface due to uniform clamping force, mold in deformation and wear a small, precision injection molding and good consistency, prolong service life of moulds; die around without any actuator the utility, periphery pipeline. Without mechanical movement of the system, mechanical, electrical transient electrical, therefore in use without maintenance, life is very long. The weaknesses of this system is: magnetic template thickness (54mm 54mm) has a certain effect on the small mould opening stroke.

Hot Products

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.